Products

- Plastic sheet equipment

-

Plastic pipe equipment

- HDPE pipe production line

- PVC(inside scerw foamed)pipe production line

- PVC wire fiber reinforced soft pipe production line

- PVC Threading pipe production line

- PPR PERT ABS PS pipe production line

- Plastic steel-plastic(wire)composite pipe production line

- Plastic fiber composite pipe production line

- Aluminum-plastic composite pipe production line

- Plastic simple-wall corrugated pipe production line

- Plastic double-wall corrugated pipe production line

- krah pipe production line

- Large diameter steel tape winding pipe production line

- Large diameter screw winding pipe production line

- PVC soft pipe production line

- EVA soft pipe production line

- Plastic foamed composite pipe production line

- Plastic seepage pipe production line

- Plastic carbon screw pipe production line

- Plastic Silicon core pipe production line

- Anti-corrosion insulation(PA foamed)pipe production line

- prestressed corrugated pipe production line

- Porous communication pipe production line

- Fiberglass pipe production line

- Small diameter plastic pipe production line

- Drip irrigation pipe production line

- PE anticorrosive pipe production line

- Wood-plastic profiles equipment

- PET PP packing equipment

- Plastic blow molding equipment

- Plastic welding equipment

- Heat-shrinkable plastic machine equipment

- Electric hot-melt sets machine

- Steel pipe anticorrosive winding machine

- Plastic machine auxiliary units

- 3D wood-plastic embossing machine

- UV Painting machinery equipment

- Wood-plastic Processing machinery equipment

- Mirror roller/pattern roller/Diping roller/wood roller

Products

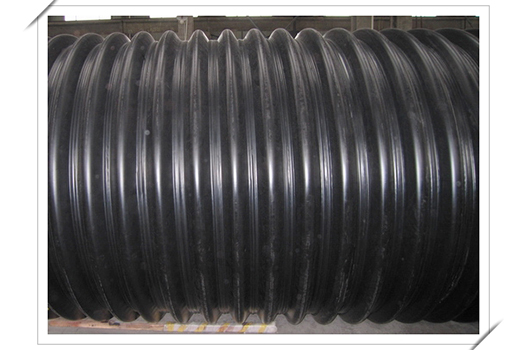

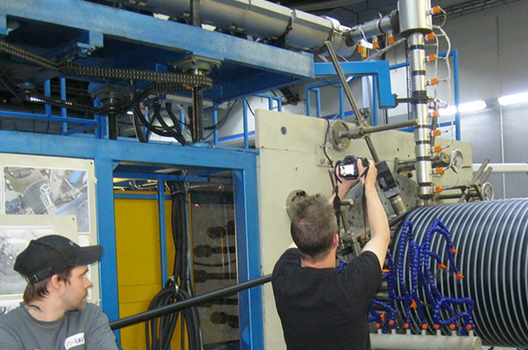

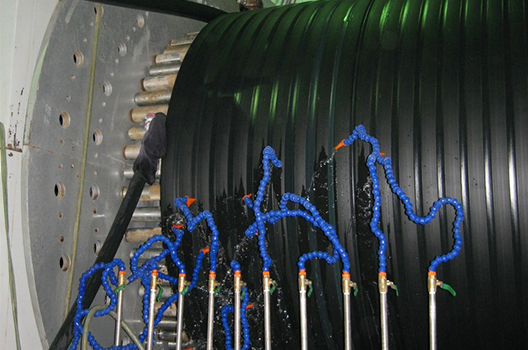

Large diameter plastic drainage pipe production line

Product details:

Since 2000 Xing Jia company began to develop large diameter plastic pipe production line, to draw the South Korean production process, continuous innovation, and gradually developed a polyethylene pipe PVC profile or steel strip, to improve the ring stiffness, reduce costs, high density polyethylene (HDPE) as raw material, through a tube, due to its unique forming process, can produce 3 meters diameter pipe. High density polyethylene (HDPE) as a result of its excellent welding performance not only ensures the product forming process and product quality, but also provides a variety of reliable methods for the construction, electric welding, heat shrink sleeve connection completely eliminate the leakage, unique environmental protection function, which provides a very effective method for the prevention and treatment of leakage pollution.

High strength, resistance is small: the structure is unique, good ring rigidity, high strength, smooth inner wall, small friction resistance, large circulation.

* installation and construction is fast, the time limit for a project is short, the weight is light, the transportation and installation is convenient, and the construction is quick;

* use long life: erosion resistant to a variety of chemical mediators; tube scaling, the basic need to dredge, buried use life of 50 years.

* excellent resistance to chemical properties: excellent acid and alkali resistance, corrosion resistance

* municipal engineering, can be used for drainage, sewage pipes, inspection wells, release flood waters

* construction works for the construction of rain water pipes, underground drainage pipes, sewage pipes, ventilation pipes, etc.

* widely used in chemical, pharmaceutical, environmental protection and other industries of sewage pipes

* agriculture, landscape engineering, irrigation and drainage for farmland, orchard, forest and tea garden

* road works, the works for the railway, highway, water seepage, drainage

* mining field, mine ventilation, drainage and water to do