Products

-

Plastic sheet equipment

- PP PE board sheet production line

- PVC board sheet production line

- ABS PS HIPS PMMA board sheet production line

- Hollow cross board production line

- Plastic hollow building template production line

- Plastic wavy board,glazed tile production line

- PVC foamed skinning board production line

- PVC free foamed production line

- XPS foamed board production line

- EPE foamed board/sheet/pipe/rod production line

- PVC mat production line

- PVC spinning mats production line

- Seepage board production line

- Stretch winding film production line

- Wide waterproof film production line

- Imitation marble (wood-grain) plate production line

- Plastic turf production line

- Plastic pipe equipment

- Wood-plastic profiles equipment

- PET PP packing equipment

- Plastic blow molding equipment

- Plastic welding equipment

- Heat-shrinkable plastic machine equipment

- Electric hot-melt sets machine

- Steel pipe anticorrosive winding machine

- Plastic machine auxiliary units

- 3D wood-plastic embossing machine

- UV Painting machinery equipment

- Wood-plastic Processing machinery equipment

- Mirror roller/pattern roller/Diping roller/wood roller

Products

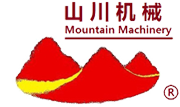

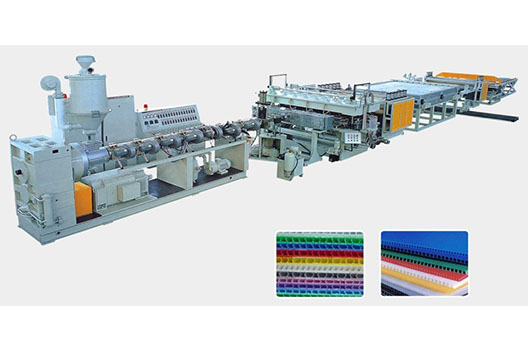

PC、PP、PE Hollow Cross sheet production line Plastic hollow building template production line

Product details:

PC sunshine board applications:

Skylights office buildings, halls, shopping malls, stadiums and public facilities.

Station, parking lot, gazebo, lounge corridor canopy.

Highway and urban elevated road noise barriers.

applications:

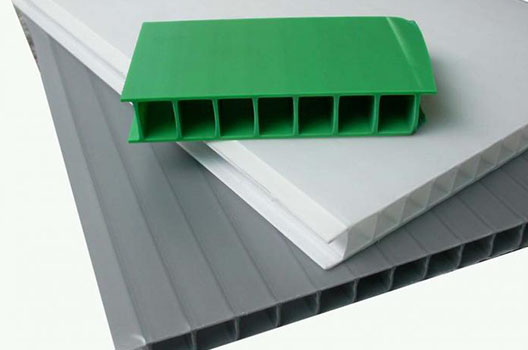

PP Hollow Cross plate due to a light weight, high strength, moisture, good environmental performance and secondary processing performance, can be processed into crates, boxes and so on.

Hollow cross sheet production line features:

1, the whole line with advanced technology, high speed, extruder use high-speed screw,high output .

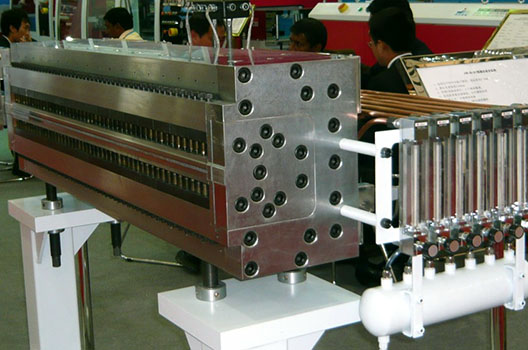

2, mold, setting board and the unique design of the cooling system and vacuum system to ensure high-speed extrusion stereotypes; abrasion resistance, dust resistance, good shape, easier to operate.

3, a special annealing furnace design, easier to control the flatness of the plate;

4, softness pull rolls according to customer requirements;

5, anti-UV can be single-sided coextrusion layer may, in accordance with the outer surface of the structural requirements can be smooth or sandblasting treatment.

| main technical parameters | ||||

| specification | SJ120/35、SJ45/30 | SJ100/38、SJ45/30 | SJ120/33 | SJ100/33 |

| materials | PC | PC | PP、PE | PP、PE |

| product width | 2100mm | 1300mm | 2100mm | 1300mm |

| product thickness | 2-40mm | 2-10mm | 2-8mm | 1.5-8mm |

| main motor power | 250kw/18.5kw | 132kw/18.5kw | 132kw | 110kw |

| max output | 450kg/h | 300kg/h | 350kg/h | 200kg/h |