Products

-

Plastic sheet equipment

- PP PE board sheet production line

- PVC board sheet production line

- ABS PS HIPS PMMA board sheet production line

- Hollow cross board production line

- Plastic hollow building template production line

- Plastic wavy board,glazed tile production line

- PVC foamed skinning board production line

- PVC free foamed production line

- XPS foamed board production line

- EPE foamed board/sheet/pipe/rod production line

- PVC mat production line

- PVC spinning mats production line

- Seepage board production line

- Stretch winding film production line

- Wide waterproof film production line

- Imitation marble (wood-grain) plate production line

- Plastic turf production line

-

Plastic pipe equipment

- HDPE pipe production line

- PVC(inside scerw foamed)pipe production line

- PVC wire fiber reinforced soft pipe production line

- PVC Threading pipe production line

- PPR PERT ABS PS pipe production line

- Plastic steel-plastic(wire)composite pipe production line

- Plastic fiber composite pipe production line

- Aluminum-plastic composite pipe production line

- Plastic simple-wall corrugated pipe production line

- Plastic double-wall corrugated pipe production line

- krah pipe production line

- Large diameter steel tape winding pipe production line

- Large diameter screw winding pipe production line

- PVC soft pipe production line

- EVA soft pipe production line

- Plastic foamed composite pipe production line

- Plastic seepage pipe production line

- Plastic carbon screw pipe production line

- Plastic Silicon core pipe production line

- Anti-corrosion insulation(PA foamed)pipe production line

- prestressed corrugated pipe production line

- Porous communication pipe production line

- Fiberglass pipe production line

- Small diameter plastic pipe production line

- Drip irrigation pipe production line

- PE anticorrosive pipe production line

- Wood-plastic profiles equipment

-

PET PP packing equipment

- Plastic blow molding equipment

- Plastic welding equipment

-

Heat-shrinkable plastic machine equipment

-

Electric hot-melt sets machine

-

Steel pipe anticorrosive winding machine

-

Plastic machine auxiliary units

- Plastic crusher

- No chip cutting machine

- Plastic mixer unit

- Plastic simple-screw extruder

- Plastic Grinder

- Plastic granulating units

- Plastic pipe/sheet mould

- Plastic dryer

- Plastic pipe belling machine

- Plastic vacuum screw feeder

- Hydraulic Automatic screen changer

- Melt pump

- Mold temperature machine

- Plastic double-screw extruder

- Winder

- 3D wood-plastic embossing machine

-

UV Painting machinery equipment

- Wood-plastic Processing machinery equipment

-

Mirror roller/pattern roller/Diping roller/wood roller

Products

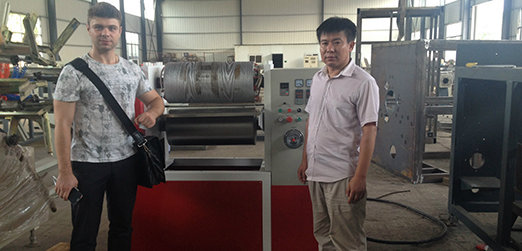

PET PP packing belt production line

Product details:

Xing jia company specializing in the production of PET packing belt production line, PET packing belt, also called plastic belt, polyester strapping belt, long-term use of temperature can reach 120 ℃, is a kind of PET (water bottles recycling material) as the main raw material through special process of high strength, high strength of new plastic packing belt. PET packing belt have the same strength and with steel belt tension, keeping the extensibility of the plastic products and contract performance, to ensure that the goods from external shocks in the package materil strip break out. In addition, compared with steel belt, PET packing belt also has safety and environmental protection, never rust, low cost, convenient operation and other advantages. Accordingly, gradually become the international used to replace steel strip of a new type of environmentally friendly packaging materials. Model steel belt according to its application into smooth plastic belt, embossed plastic belt and black plastic belt.

Is now widely used in wood, paper, steel, aluminum, steel pipes, profiles, glass, building materials, ceramics, electrical appliances, metal products, tobacco, chemical fiber, cotton, etc. Transparent appearance, smooth or prismatic.

PET打包带参数:

| Width/mm | Thickness/mm | Min tensile fracture load/KN | ||

| H | M | L | ||

| 9 | 0.6 | 2.38 | 2.13 | 1.89 |

| 12 | 0.6 | 3.17 | 2.84 | 2.52 |

| 16 | 0.6 | 4.22 | 3.79 | 3.36 |

| 16 | 0.8 | 5.63 | 5.06 | 4.48 |

| 19 | 0.8 | 6.69 | 6 | 5.32 |

| 19 | 1 | 8.36 | 7.51 | 6.65 |

| 19 | 1.2 | 10.03 | 9.01 | 7.98 |

| 25 | 1 | 11 | 9.88 | 8.75 |

| 25 | 1.2 | 13.2 | 11.85 | 10.5 |

| 32 | 1 | 14.08 | 12.64 | 11.2 |

| 32 | 1.2 | 16.9 | 15.17 | 13.44 |

PP packaging tapes made from the raw material polypropylene modified high quality additives, effectively improve you pack the product performance, improve the flexibility and hardness, can be effective within the portal frame of full automatic packing machine. You pack after six steps: high temperature extrusion, stretching, pressing, cooling and shaping, winding packaging production technology refined but become, pack the width and thickness of high precision and uniform density; Strong adhesive force, pulling force is large, light quality, corrosion resistance, appearance beautiful, upscale. In addition, both the left and right sides of the straps have edge lines, and can effectively improve the tighten force, is the automatic packing machine and fully automatic unmanned packer's ideal material.