Products

-

Plastic sheet equipment

- PP PE board sheet production line

- PVC board sheet production line

- ABS PS HIPS PMMA board sheet production line

- Hollow cross board production line

- Plastic hollow building template production line

- Plastic wavy board,glazed tile production line

- PVC foamed skinning board production line

- PVC free foamed production line

- XPS foamed board production line

- EPE foamed board/sheet/pipe/rod production line

- PVC mat production line

- PVC spinning mats production line

- Seepage board production line

- Stretch winding film production line

- Wide waterproof film production line

- Imitation marble (wood-grain) plate production line

- Plastic turf production line

- Plastic pipe equipment

- Wood-plastic profiles equipment

- PET PP packing equipment

- Plastic blow molding equipment

- Plastic welding equipment

- Heat-shrinkable plastic machine equipment

- Electric hot-melt sets machine

- Steel pipe anticorrosive winding machine

- Plastic machine auxiliary units

- 3D wood-plastic embossing machine

- UV Painting machinery equipment

- Wood-plastic Processing machinery equipment

- Mirror roller/pattern roller/Diping roller/wood roller

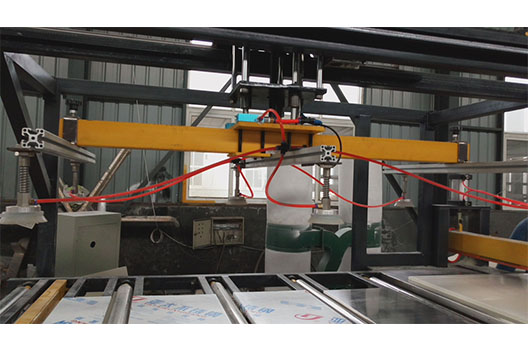

PVC skinning (WPC) foam sheet production line

Product details:

In 2011 the company successfully developed the PVC foam board, PVC foam board is also called the chevron board and Andy board, PVC foam board. Widely used in buses, trains ceiling, box core, interior decoration board, building wall panels, interior decoration and board, office, residential, public building compartment and commercial decorative frame, clean room board, ceiling board, screen printing, computer engraving, advertising signs, panels, signs with album board board industry and chemical anti-corrosion engineering, thermoforming, with cold plate, special cold preservation engineering, environmental protection plate model, sports equipment, breeding of material, beach moistureproof facilities, waterproof material, art materials and a variety of lightweight partition board instead of a glass ceiling.

According to the production process of PVC foam board can be divided into PVC PVC skin foam board and free foaming boardPVC

PVC skin foam board surface hardness is very high, it is difficult to produce scratches, widely used in cabinets, decoration, construction, etc.

The surface hardness of PVC free foam board, widely used in advertising display boards, mounting board, screen printing, carving etc.

1, a sound and heat insulation, thermal insulation, flame retardant, moistureproof, mouldproof, shockproof, weather resistant, not easy to change, easy printing performance.

2, with material light, storage and transportation, construction convenience.

3, the use of ordinary wood processing tool can be like the same as the wood drilling, sawing, nailing, planing, sticky processing construction

4, can be applied to hot forming, heat bending and folding process, according to the general welding procedure welding, and other PVC material bonding.

Product specifications: 1220*2440mm, (specially produced 1560*3050mm, 2050*3050mm)

Product thickness: 3-20mm (20-33mm)

Product density: 0.35-0.9