Products

- Plastic sheet equipment

-

Plastic pipe equipment

- HDPE pipe production line

- PVC(inside scerw foamed)pipe production line

- PVC wire fiber reinforced soft pipe production line

- PVC Threading pipe production line

- PPR PERT ABS PS pipe production line

- Plastic steel-plastic(wire)composite pipe production line

- Plastic fiber composite pipe production line

- Aluminum-plastic composite pipe production line

- Plastic simple-wall corrugated pipe production line

- Plastic double-wall corrugated pipe production line

- krah pipe production line

- Large diameter steel tape winding pipe production line

- Large diameter screw winding pipe production line

- PVC soft pipe production line

- EVA soft pipe production line

- Plastic foamed composite pipe production line

- Plastic seepage pipe production line

- Plastic carbon screw pipe production line

- Plastic Silicon core pipe production line

- Anti-corrosion insulation(PA foamed)pipe production line

- prestressed corrugated pipe production line

- Porous communication pipe production line

- Fiberglass pipe production line

- Small diameter plastic pipe production line

- Drip irrigation pipe production line

- PE anticorrosive pipe production line

- Wood-plastic profiles equipment

- PET PP packing equipment

- Plastic blow molding equipment

- Plastic welding equipment

- Heat-shrinkable plastic machine equipment

- Electric hot-melt sets machine

- Steel pipe anticorrosive winding machine

- Plastic machine auxiliary units

- 3D wood-plastic embossing machine

- UV Painting machinery equipment

- Wood-plastic Processing machinery equipment

- Mirror roller/pattern roller/Diping roller/wood roller

Products

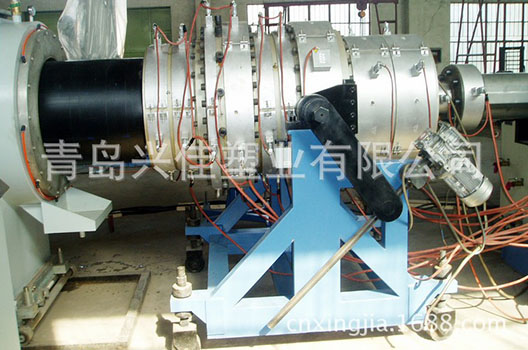

Plastic Pipe Production Line

Product details:

Xingjia company specializing in the production of plastic pipe production line:

1. Rigid PVC (UPVC) pipe

2. chlorinated polyvinyl chloride (CPVC) pipes (PVC spiral drain pipe inside the hollow, cable communication pipe)

3. Polyethylene (PE) pipes (water pipes, gas pipes)

The cross-linked polyethylene (PE-X) pipe

5. The three polypropylene (PP-R) pipe (building water pipe)

6. polybutylene (PB) pipe

7. plastic (ABS) pipe

8. Fiberglass Reinforced Plastic (RPM) pipe

9. plastic composite (PAP) tube

10. The plastic composite (SP) tube

11. Silicon tube (cable communication tube)

Plastic pipe production process:

raw material mixture --Feeding metering—Extruder--Pipe die--Calibrating water tank--Cooling water tank—Maji—Tractor--Chipless cutting machine--Stacking platform(Winding Machine)

Plastic pipe as an important part of chemical building materials, with its superior performance, health, environmental protection, low consumption and other widely accepted by the majority of users, compared with the traditional plastic pipe cast iron pipe, galvanized steel pipes, cement pipes and other pipes, having energy and materials, environmental protection, high-strength lightweight, corrosion-resistant, smooth wall does not scale, simple construction and maintenance, long life and other advantages, widely used in building water supply and drainage, urban and rural water supply and drainage, city gas, electricity and the cable jacket, industrial fluid transport, agriculture and irrigation construction, municipal, industrial and agricultural fields.