Products

-

Plastic sheet equipment

- PP PE board sheet production line

- PVC board sheet production line

- ABS PS HIPS PMMA board sheet production line

- Hollow cross board production line

- Plastic hollow building template production line

- Plastic wavy board,glazed tile production line

- PVC foamed skinning board production line

- PVC free foamed production line

- XPS foamed board production line

- EPE foamed board/sheet/pipe/rod production line

- PVC mat production line

- PVC spinning mats production line

- Seepage board production line

- Stretch winding film production line

- Wide waterproof film production line

- Imitation marble (wood-grain) plate production line

- Plastic turf production line

-

Plastic pipe equipment

- HDPE pipe production line

- PVC(inside scerw foamed)pipe production line

- PVC wire fiber reinforced soft pipe production line

- PVC Threading pipe production line

- PPR PERT ABS PS pipe production line

- Plastic steel-plastic(wire)composite pipe production line

- Plastic fiber composite pipe production line

- Aluminum-plastic composite pipe production line

- Plastic simple-wall corrugated pipe production line

- Plastic double-wall corrugated pipe production line

- krah pipe production line

- Large diameter steel tape winding pipe production line

- Large diameter screw winding pipe production line

- PVC soft pipe production line

- EVA soft pipe production line

- Plastic foamed composite pipe production line

- Plastic seepage pipe production line

- Plastic carbon screw pipe production line

- Plastic Silicon core pipe production line

- Anti-corrosion insulation(PA foamed)pipe production line

- prestressed corrugated pipe production line

- Porous communication pipe production line

- Fiberglass pipe production line

- Small diameter plastic pipe production line

- Drip irrigation pipe production line

- PE anticorrosive pipe production line

- Wood-plastic profiles equipment

-

PET PP packing equipment

- Plastic blow molding equipment

- Plastic welding equipment

-

Heat-shrinkable plastic machine equipment

-

Electric hot-melt sets machine

-

Steel pipe anticorrosive winding machine

-

Plastic machine auxiliary units

- Plastic crusher

- No chip cutting machine

- Plastic mixer unit

- Plastic simple-screw extruder

- Plastic Grinder

- Plastic granulating units

- Plastic pipe/sheet mould

- Plastic dryer

- Plastic pipe belling machine

- Plastic vacuum screw feeder

- Hydraulic Automatic screen changer

- Melt pump

- Mold temperature machine

- Plastic double-screw extruder

- Winder

- 3D wood-plastic embossing machine

-

UV Painting machinery equipment

- Wood-plastic Processing machinery equipment

-

Mirror roller/pattern roller/Diping roller/wood roller

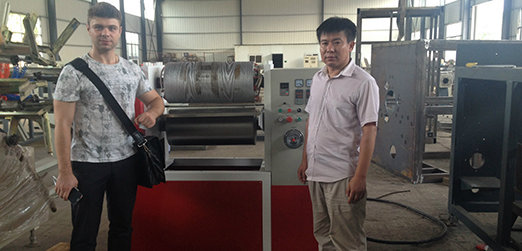

wood-plastic embossing machine

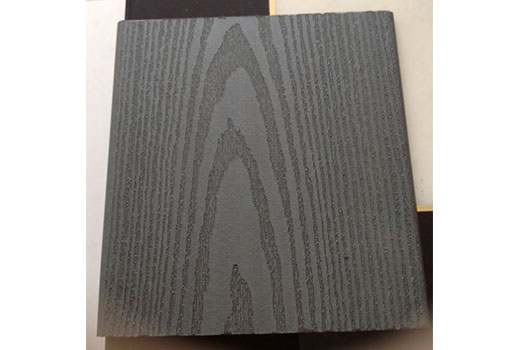

Product details:

Qingdao Xingjia Plastic Industry Co., Ltd. specializing in the production: wood-plastic embossing machine

The company's wood-plastic embossing machine dedicated to supporting wood-plastic machinery production lines, advanced technology, reliable quality, production stability, and has a variety of embossing function. According to the user to provide a variety of pattern samples produced a variety of roller mold, novel style, full-featured, nice, economical and practical.

First, the wood plastic embossing machine high 1380 × width 1920 × length 2250, grain width 400-1200mm, is a suitable type, cost-effective and practical models. If the user has special requirements, our company can be based on user requirements, adjust the width of wood, depending on the specific requirements and custom.

Second, in order to improve the quality of wood products, the wood plastic embossing machine installed a heating device. Using intelligent digital automatic detection and control instruments, with high display accuracy, good temperature control performance, strong earthquake resistance, good reliability, clear reading, no parallax characteristics. The temperature can be arbitrarily set from 0 ℃ -250 ℃, automatic control, in full compliance with the requirements of wood and plastic embossed.

Third, the wood products of different thickness, the structure is more complex. The wood plastic embossing machine according to this feature, increased the two roller adjustment room, embossed product thickness can be between 0-150mm distance between the arbitrary adjustment. The machine adopts the advanced small manual hydraulic pump station, the manual mechanical energy can be converted into liquid pressure energy, driven by any two cylinder up and down regulation, the pressure control between 1Mpa-19Mpa to ensure that in the production process can always maintain enough pressure.

Fourth, the wood plastic embossing machine can adjust the embossing speed of any function, the machine uses advanced cycloid reducer, and with the 2.2 kW inverter motor. Users can set the speed according to the needs of embossed products between 0-20m / min. So that embossed product lines clear, smooth, beautiful and durable.

Fifth, the company uses advanced CNC engraving technology and sophisticated laser layout erosion process, pressed out of wood plastic pattern clear, vivid, three-dimensional pattern of strong patterns.